Simplifying manufacturing processes using CAD

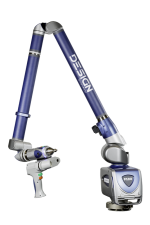

As we all know, manufacturing is the production of merchandise for sale; using labor, machines and tools. Manufacturing process management refers to the technologies and methods that determine how labor, machines, and tools are put to use during production. For manufacturers, planning manufacturing processes can pose some difficulties. Hence the need for large enterprises to hire project managers. But for small manufacturing businesses, hiring a project manager may not be practical. And this is where the need to consider other planning and execution techniques come in. Using CAD for Product Design Designing a functioning prototype is the first stage of the product manufacturing process and with the aid of 3D CAD applications like Autodesk’s Maya or Microstation, a realistic representation of your product can be designed, analysed and have its functionalities tested to gauge its performance once built. These techniques are being used every day by both major corporations and SMEs to save cost as the following case study will show. GINTIC Institute of CIM—a national Research & Development (R&D) Center and a BIM company in Singapore—have continuously made use of CAD techniques to simplify their production processes in multiple ways. In 2014, GINTIC commenced the design of knee-joint prosthesis uniquely suited to Asians in order to reduce muscle strain cue to continuous kneeling. To accomplish this, the Singaporean institute made use of CAD applications to design the prototype and test its efficacy in order to cut cost before production. This new project adds to GINTIC’s use of CAD as a product design tool and its previous success in using CAD to design jewelries and a lightweight, diskless laptop computer means this new goal is certainly achievable with the aid of computer aided design techniques. Using CAD for Product Testing Computer aided design also helps simplify the processes involved […]