Smarter growth, lower risk: Rethinking how new factories are built

A tailored, thoughtful combination of cutting-edge technologies, stronger contracting skills, and deep supply chain capabilities can get a new factory up and running—without costly delays. Today’s environment is giving manufacturers even more reasons to reassess their footprint strategies. For some, localisation of production may now seem increasingly attractive—particularly amid rising volatility […]

Zenno Astronautics and ANA Trading rollout superconducting space technologies in Japan

New Zealand-headquartered Zenno Astronautics (Zenno), the space superconductor company, has signed a Memorandum of Understanding (MOU) with ANA Trading to deploy Zenno’s superconducting technologies for space applications in the Japanese market. ANA Trading is a member of ANA Group, Japan’s leading airline group. With the slogan “Next Stop, Space”, ANA Group has […]

Countries successfully growing their manufacturing – and what they are doing right

From Brazil to Singapore, here’s how six countries are rethinking manufacturing. From the climate crisis and geopolitical headwinds to next-generation technologies, a series of complex challenges are rewriting the rulebook for global value chains. Against this backdrop, what are manufacturers and supply chain companies doing to ensure their operations are […]

Masdar City’s Net-Zero Model Sets Sustainability Benchmark, but AI Holds Key for Aging Cities, Experts Claim

A new white paper from Masdar City highlights the UAE’s leadership in net-zero urban development. Energy experts say that net-zero strategies could also be applied to most cities worldwide, even when the biggest challenge is in retrofitting old existing buildings. Built as a purpose-driven net-zero city, Masdar eliminates the need […]

How manufacturers can adapt to workforce changes through flexible working environments

Liam Merrick, sales engineer, ECI Solutions New Zealand’s manufacturing sector faces a significant challenge amid an ongoing skills and labour shortage. The Employers and Manufacturers Association (EMA) reports that 71 per cent of employers can’t find skilled people, an increase from 40 per cent in 2022, and 90 per cent […]

From Survive to Thrive: FMCG Strategies for Growth and Profitability in 2025

Chris Foord, Partner, Argon & Co New Zealand As we look forward to 2025 the outlook for business and NZ are improving. Many businesses in 2024 were focused on the “survive till 2025” mindset, controlling costs and avoiding discretionary spend. Very few though forgot about the consumer/customer and the need […]

How to build the skills needed for the age of AI

AI is changing how we work and what skills workers need to thrive in a world of intelligent machines and cognitive computing. Only a sliver of education initiatives are devoted to AI and these are not yet integrated into most education systems. Collaborative initiatives between education and industry can accelerate […]

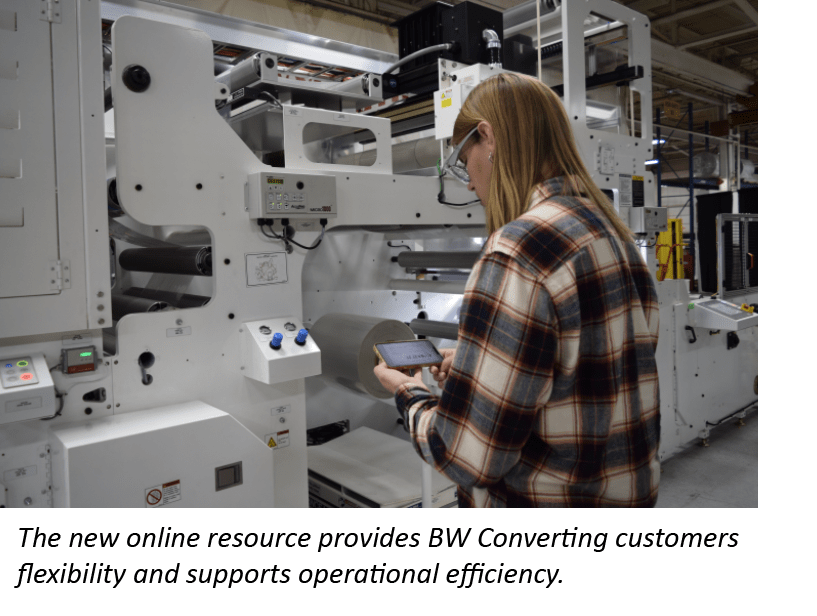

BW Converting launches e-learning platform for enhanced customer training

New online training solution complements on-site training, offers flexible learning options and helps customers manage workforce challenges BW Converting has launched an e-learning platform aimed at transforming customer training across its entire brand portfolio. Designed to provide flexibility and support operational efficiency, this online resource allows customers to access detailed […]

Clearing the Way: Accelerating Industry 4.0 Adoption through Global Benchmarking

Adam Sharman, Senior Partner, Dsifer Introduction As organisations look for productivity gains, competitive advantages in agility scalability and sustainability, more and more are looking to technology to support, augment or accelerate their operations. A recent report from Westpac identified that, whilst digital tech adoption is growing, New Zealand’s manufacturers have […]

Securing the Smart Factory

Attributed to: Alex Nehmy, Field Chief Security Officer, Critical Industries, Japan & Asia Pacific, Palo Alto Networks The incredibly competitive manufacturing industry has evolved from labour-intensive manual processes to progressively more intelligent systems driven by the computing power of the digital revolution. Even more so with the supply chain shifts […]

Manufacturing and Production Industry is Fighting a 41% Increase in Ransomware Attacks over Four Years

By Sandra Lee, Managing Director of Southeast Asia and Korea, Sophos Wrapping up the first half of 2024, the Asia-Pacific region (APAC) is set to be the fastest growing region of the world economy1. It accounted for more than half of global GDP growth with the manufacturing industry becoming one […]

CT Semiconductor Inaugurates ATP Chip Semiconductor Training Center

HANOI, Vietnam. On October 1st, 2024, The ATP Semiconductor Chip Technician Training Center CT Semiconductor (a member of CT Group) was officially inaugurated and commenced operations at the National Innovation Center (NIC) in Hoa Lac High-Tech Park, Hanoi. The ATP Semiconductor Chip Technician Training Center at NIC is part of […]

Productivity is the only game in town!

Ian Walsh, Partner, Argon & Co It is great to see that finally we are talking as a nation about the need to be more productive. Our poor performance in productivity terms is not a new issue or problem, but given the current economic environment, it has become clear to everyone that we have a significant gap to countries with which we compare ourselves. The consequences of this are significant, with many young New Zealanders leaving for foreign shores for better pay, conditions and quality of life. This problem has been disguised for decades by global financial crises, pandemics, earthquakes and media misdirection (“We are the most liveable country!”, “Auckland is one of the top 10 cities!” etc.). Like climate change it has been possible to ignore for a long time. However, most of us are aware that our infrastructure is creaking. We can’t invest in health education, police, transport and other programs to the extent that we would like to, as we can’t afford it. Productivity is essential for economic growth, competitiveness, profitability, job creation, resource efficiency, and work-life balance. Focusing on productivity improvements at individual, organizational, and national levels can lead to numerous benefits and contribute to overall prosperity I have been to many business meetings, and the focus for any improvement drive is return on investment – they are asking whether investing in an activity makes the business more profitable, more competitive and ultimately whether it will result in better return for shareholders, so they can invest in future programs to improve the product or service, grow the business and offer better products or services. The same is true at a national level, the government can only spend what the economy generates (balanced budgets and low debt). Profit (or in more political termianology, surplus) needs to be […]