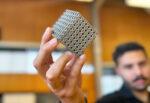

3D printed titanium structure shows supernatural strength

A 3D printed ‘metamaterial’ boasting levels of strength for weight not normally seen in nature or manufacturing could change how we make everything from medical implants to aircraft or rocket parts. RMIT University researchers created the new metamaterial – a term used to describe an artificial material with unique properties not observed in nature – from common titanium alloy. But it’s the material’s unique lattice structure design, recently revealed in the journal Advanced Materials, that makes it anything but common: tests show it’s 50% stronger than the next strongest alloy of similar density used in aerospace applications. Improving on nature’s own design Lattice structures made of hollow struts were originally inspired by nature: strong hollow-stemmed plants like the Victoria water lily or the hardy organ pipe coral (Tubipora musica) showed us the way in combining lightness and strength. However, as RMIT’s Distinguished Professor Ma Qian explains, decades of trying to replicate these hollow ‘cellular structures’ in metals has been frustrated by the common issues of manufacturability and load stress concentrating on the inside areas of the hollow struts, leading to premature failures. “Ideally, the stress in all complex cellular materials should be evenly spread,” Qian explained. “However, for most topologies, it is common for less than half of the material to mainly bear the compressive load, while the larger volume of material is structurally insignificant.” Metal 3D printing provides unprecedented innovative solutions to these issues. By pushing 3D printing design to its limits, the RMIT team optimized a new type of lattice structure to distribute the stress more evenly, enhancing its strength or structural efficiency. “We designed a hollow tubular lattice structure that has a thin band running inside it. These two elements together show strength and lightness never before seen together in nature,” said Qian. “By effectively merging two […]