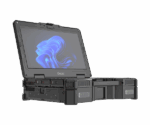

Emerson’s next-generation of industrial PCs for AI-enabled automation

New PACSystems IPCs combine latest generation of industrial-rated processors with optimised cooling and pre-loaded software to simplify advanced computing and integration. Emerson has the PACSystems IPC 6010, IPC 7010, and IPC 8010 industrial computing platforms. This new line expands Emerson’s family of high-performance industrial personal computer (IPC) models for demanding applications, including artificial intelligence, machine learning and advanced analytics. PACSystems IPCs feature the first CPU in the latest generation of processors designed specifically to support AI enabled capabilities such as predictive maintenance, process optimization, quality inspection, decision support, supply chain management and more. Critical digital transformation applications require reliable and ruggedised computing platforms, with the high level of performance needed to support data collection, protocol conversion, historisation, and analytics for real-time optimisation and visualszation capabilities. The new PACSystems line features significant performance updates and more options to develop solutions for challenging industrial applications, with a range of functionality and price points to support scalable operations and lower cost-of-ownership. The new line of IPCs use the latest generation of soldered industrial-rated 13th Generation Intel Core Processors with up to 64 GB soldered ECC memory, for maximum resistance against shock and vibration. Their compact form factor employs fan-less cooling for an extended operating temperature range up to 70 degrees Celsius, with thermal monitoring and an optional fan available for high-temperature environments. PACSystems IPCs benefit from Emerson’s patented vibration and thermal technologies to boost reliability and extend deployment life.With solid-state drive (SSD) storage options ranging up to 4 terabytes, multiple gigabit Ethernet interfaces, up to four PCIe® slots, and other interfaces, PACSystems IPCs can be tailored to deliver high-performance computing required for vision systems, advanced analytics, data processing, historization/visualization, and other similarly rigorous functions for process optimisation and improved operational insight. Available pre-installed, pre-licensed operating systems with edge and visualisation software help to […]